Low Voltage Pure Sine Wave Inverter

Basic Info

Model No.: FG100A

Product Description

In terms of capacity, most general-purpose inverters have parameters such as rated current, available motor power and rated capacity. How to calculate vfd speed. This FGI FG100A series Low Voltage Pure sine wave inverter features overload capacity, start torque and flying start function. This Low Voltage Charging Inverter has good performance and high reliability, low voltage working principle of inverter ppt can be widely used to textile, paper, wire drawing, machine tools, pumps and various automated production equipment. And we combined with relevant application features, improve its reliability and optimal design, the low voltage inverter can satisfy the requirements for various applications without Low Voltage Inverter Problem.

Structure---Parts of Low Voltage Inverter

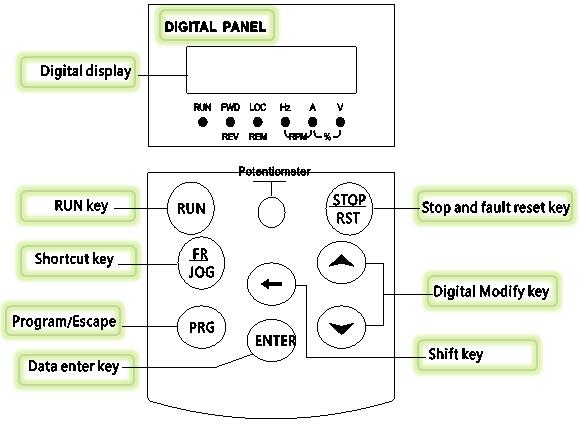

Keypad Schematic Diagram

Functional key description

Program/Escape---Enter or escape from the first level menu.

Data enter Key---Progressively enter menu and confirm parameters.

Digital modify key---Progressively increase data or function codes.

Digital modify key---Progressive decrease data or function codes.

Shift Key---In parameter setting mode, press this button to select the bit to be modified. In other modes, cyclically displays parameters by right shift.

Run Key---Start to run the inverter in keypad control mode.

Stop/Reset Key---In running status, restricted by P7.04, can be used to stop the inverter. When fault alarm, can be used to reset the inverter without any restriction.

Shortcut Key---Determined by Function Code P7.03: 0:splay status switching, 1:jog operation, 2:Switch between forward and reverse, 3:Clear the UP/DOWN terminals settings, 4:Quick debugging mode

Combination Key---Pressing the [RUN] and [STOP/RST] at the same time can achieve inverter coast to stop.

Technology Features

Input & Output

Input Voltage Range: 380-480V/690V±10% Input Frequency Range: 47~63Hz

Output Voltage Range: 0~rated input voltage Output Frequency Range: 0〜400Hz

I/O Features

Programmable Digital Input: Provide 7 terminals which can support ON-OFF inputs, 1 terminal which can support high speed pulse input and support PNP, NPN

Programmable Analog Input: AI1 can accept input of -10V 〜10V,AI2 can accept input of 0〜10V or 0〜20mA.

Programmable Open Collector Output: Provide 1 output terminal (open collector output or high speed pulse output)

Relay Output: Provide 2 output terminals

Analog Output: Provide 2 output terminal, whose output scope can be 0/4~20 mA or 0〜10 V,as chosen.

Main Control Function

Control Mode: V/F control, Sensorless Vector Control (SVC), Torque control

Overload Capacity: 60s with 150% of rated current, 10s with 180% of rated current.

Speed Adjusting Range: 1:100 (SVC)

Carrier Frequency: 1 kHz ~15.0 kHz.

Frequency reference source: keypad, analog input, HDI, serial communication, multi-stage speed, simple PLC and PID setting. The combination of multi-modes and the switch between different modes can be realized.

PID Control Function

Simple PLC, Multi-Steps Speed Control Function: 16 stages speed can be set.

Traverse Control Function

None-Stop when instantaneous power off

Speed Trace Function: Smoothly start the running motor

[FR/JOG] Key: User defined shortcut key can be realized

Automatic Voltage Regulation Function (AVR):Automatically keep the output voltage stable when input voltage fluctuating

Fault protections: Protect from over current, over voltage, under voltage, over temperature, phase failure, over load etc

Performance Characteristics

200%---Overload Capacity: 160% for 60 seconds, 180% for 10 seconds, 200% for 1 second

50%---Ambient Temperature: without derating up to 50℃, optimized cooling system, robust design

180%---Start Torque: 0.5Hz/150%(V/f), 0.25Hz/180%(SVC)

±15%---Input Voltage Fluctuation: flexible with big voltage fluctuation, motor runs stably, high reliability

CPU: latest technology of TI, high speed, high performance, high reliability

Keypad: detachable, standard internet cables used, 35 meters can be extended, two lines display( >7.5kW)

Flying start function: restart the running motor smoothly, no current surge,high accuracy

IGBT: selection of large margin, current>2 times of inverter current

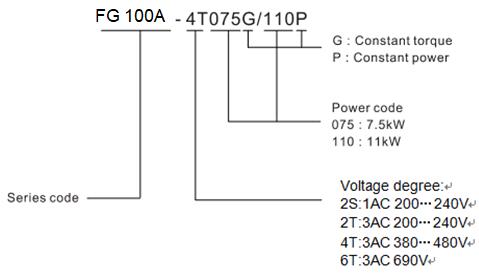

Product Model Description

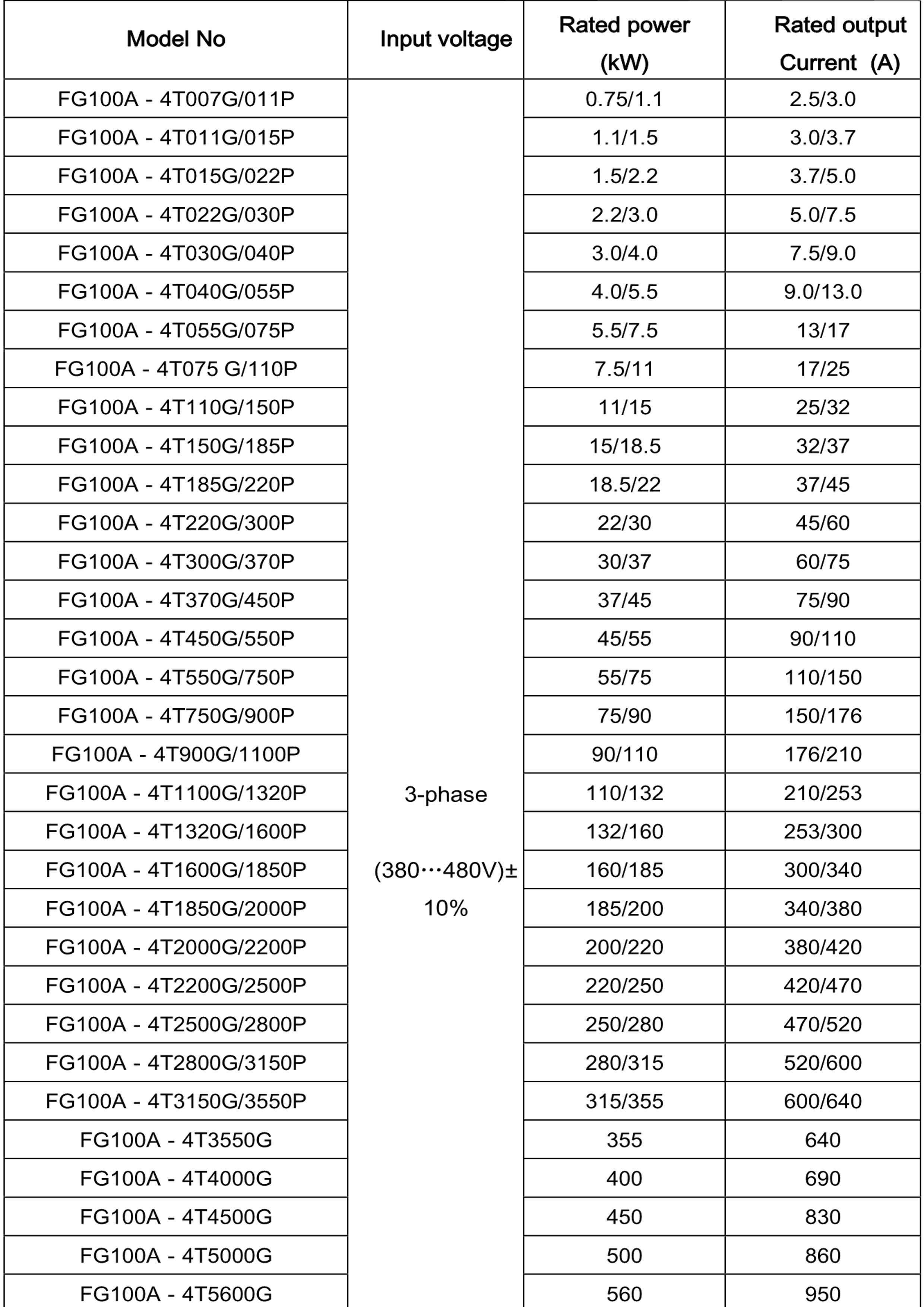

Selection Guide

Model No Input Voltage Rated power(kW) Rated Output Current(A)

FG100A-4T007G/011P 3-phase 0.75/1.1 2.5/3.0

FG100A-4T011G/015P (380-480V)±10% 1.1/1.5 3.0/3.7

FG100A-4T015G/022P 1.5/2.2 3.7/5.0

---

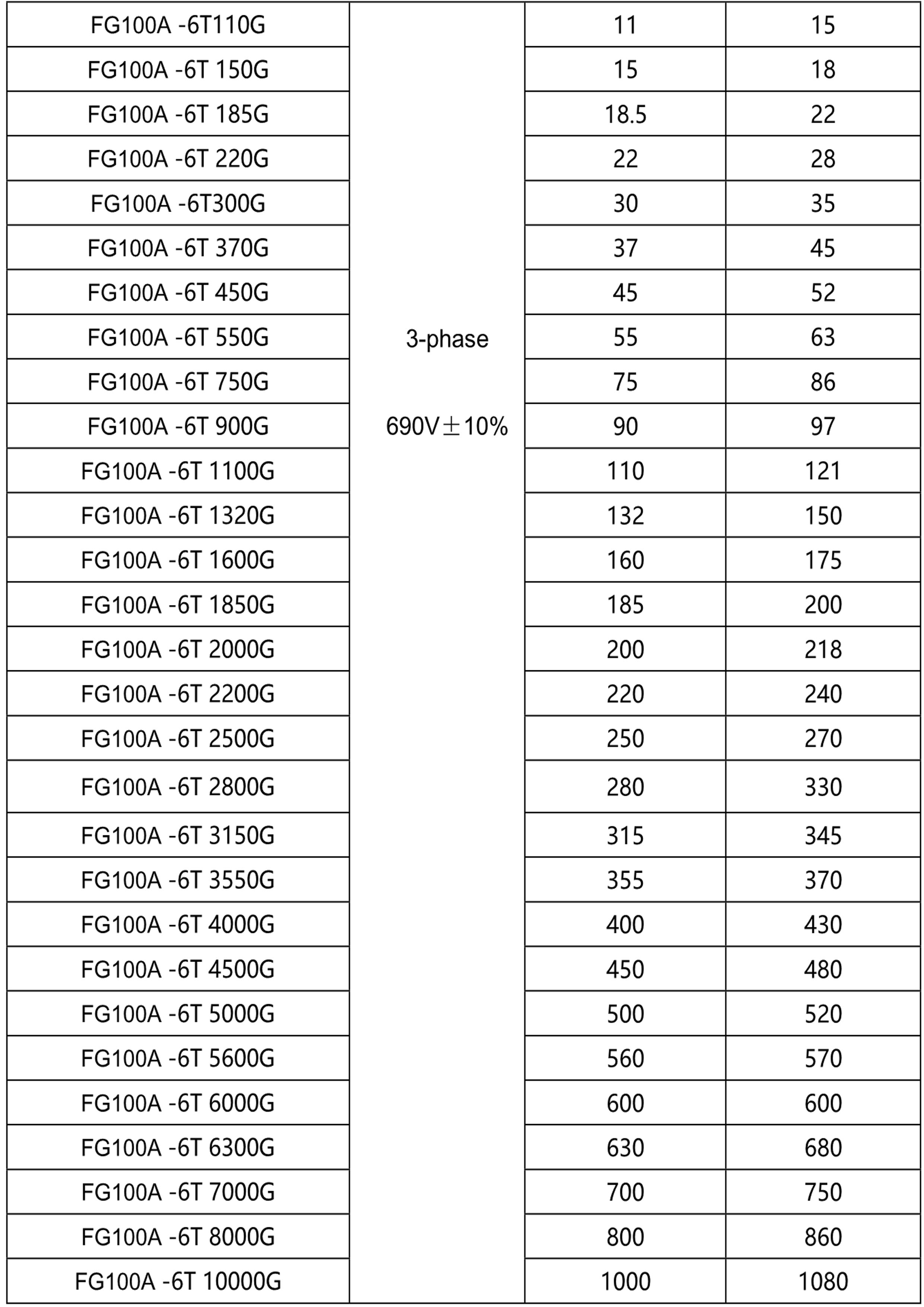

FG100A-6T110G 3-phase 11 15

FG100A-6T150G 690V±10% 15 18

FG100A-6T185G 18.5 22

---

Main Features

Wide Range of Applications

Open-loop vector control, suitable for most applications, no need to separately stock different inverters for different motors;

Excellent Performance

Good control performance: 0.25Hz/150% starting torque, multiple braking modes for fast braking;

Strong Environmental Adaptability

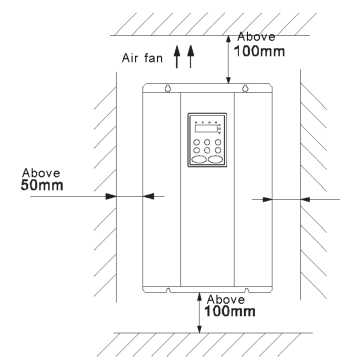

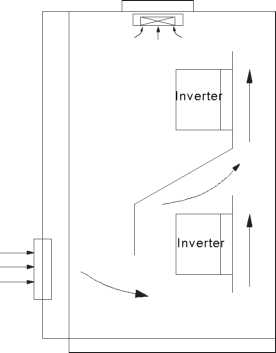

Compact structure design, independent air duct design, multiple installation methods, greatly increased power density, effectively reducing user installation volume requirements, meeting demanding user installation conditions;

The fully independent air duct design effectively improves the protection effect of the inverter and adapts to various complicated user site environments;

Rich in Function

1. Speed tracking to achieve restart of the running motor;

2. AVR (Automatic Voltage Regulation) function keeps the output voltage of the inverter stable even if the input voltage fluctuates.

3. Built-in PID function.

4. Built-in standard modbus communication protocol.

High Reliability

The thermal simulation technology was introduced, and all models were subjected to thermodynamic simulation to effectively plan the heat dissipation of the whole machine and improve product reliability.

All products have been verified by complex products such as high temperature, low temperature, low pressure, vibration, etc., ensuring the reliability of the product from the source;

Powerful hardware configuration: wide voltage range input, support for DC input, common DC bus design, built-in braking unit (less than 18.5kW), high-performance LED keyboard for external reference, numerous I/O Terminals, etc.

Multiple Options

Optional expansion options such as expansion cards, filters, auxiliary power supplies, brake units and reactors are available.

Environmental Requirement

Temperature and Humidity

The ambient temperature is among-10 °C~ +40 °C and the frequency inverter has to derate by 4% for every additional 1 °C if the ambient temperature exceeds 40 °C. The temperature cap is 50 °C. Relative humidity of the air≤ 90%. No condensation is allowed.

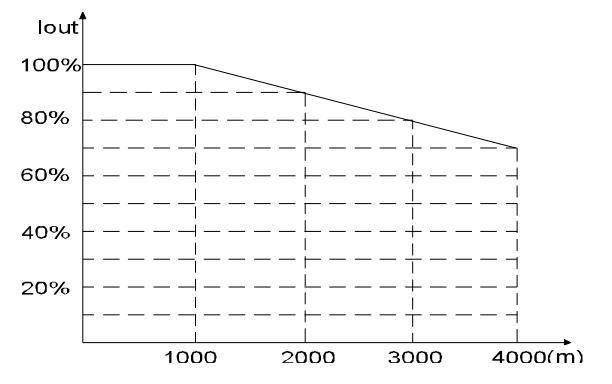

Altitude

The low voltage inverter can run at the rated power if the installation site is less than 1000m(including 1000m) above the sea level. But it has to derate if the altitude exceeds 1000m. See the following figure for details:(Relationship between output current and altitude)

Other Environment Requirements

The low voltage drives can not bear fierce impact or shock. So the oscillation range should be less than 5.8m/s2(0.6g).

The low voltage converter should keep away from the electromagnetic radiation source.

The low voltage boost converter drive should keep away from water and condensation.

The low voltage driver should keep away from contaminative air, such as corrosive gas, oil mist and conductive dust.

The low voltage inverters should keep away from direct sunlight, oil mist, steam and vibration environment.

Installation Space

Add the air deflector when apply the up-down installation.

Production Process

IQC---》SMD---》Components Test---》 PCBA Coating---》Assembly---》50 °C Aging Test(24 hours)---》Loading Test---》Packing and Dispatching

Application

Widely used in textile, paper, wire drawing, machine tools, packaging, food, fans, pumps and various automated production equipment. Providing highly integrated and integrated solutions for equipment manufacturing and end customers, it is of great help to reduce system procurement and operating costs and improve system reliability.

Our Service

OEM Service is available

After-sales responding within 24 hours

One to one pre-sales consulting services

We are factory with high-tech professional engineer teams

Technician could be assigned to go abroad to carry out site commissioning and technical training

Product Categories : AC Drives > Low Voltage Drives